Industry News

-

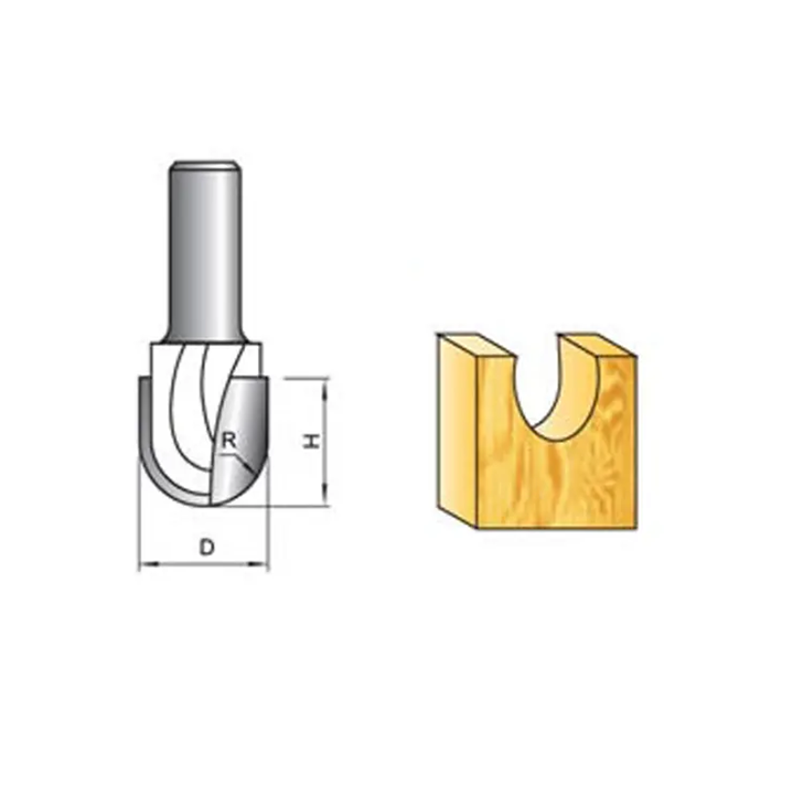

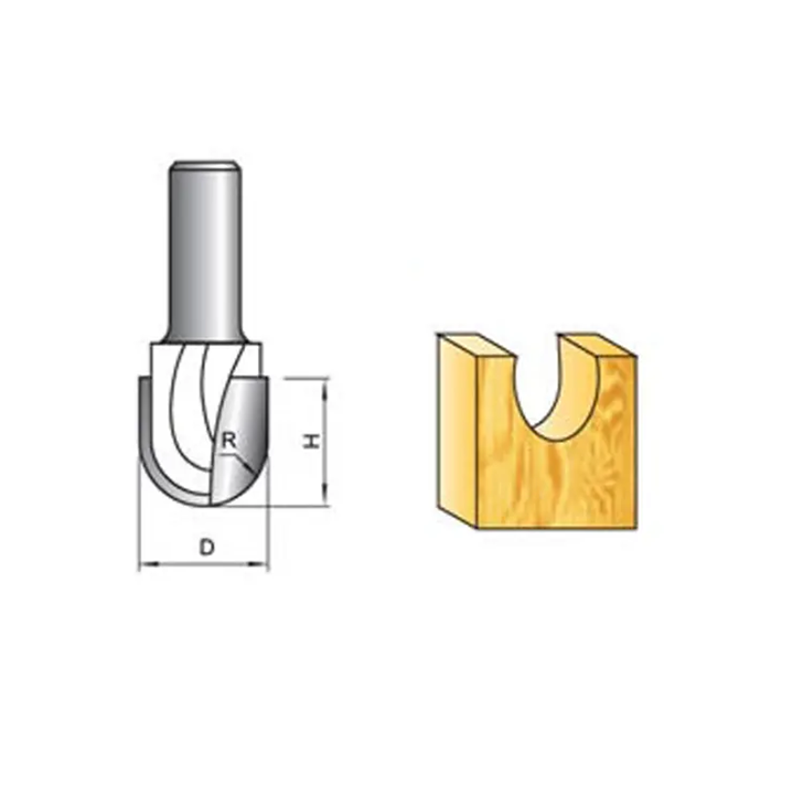

Enhance your woodworking projects with carbide fillet drill bits

Are you looking to add a professional finish to your woodworking projects? JS-TOOLS carbide round head fillet drill bit is your best choice. This versatile tool is designed to add fillet beads to the edges of shel...Read more -

Milling Cutter Versatility: A Must-Have Tool for Beveling and Edging

When it comes to precision and efficiency in woodworking, a router bit is a tool capable of creating 45-degree chamfers on boards and panels, adding a sophisticated decorative feel to the edges. This versatile tool is an essential part of any woodworking arsenal, offering a range of features and ...Read more -

Enhance your concrete drilling capabilities with the revolutionary SDS Plus chisel point, flat and gouge drill bits

When it comes to concrete drilling, having the right tools can make a world of difference. SDS Plus Chisel Point & Flat & Gouge Bit is one of the must-have tools for every professional and DIY enthusiast. This innovative drill combines cutting-edge technology with reliability so you can w...Read more -

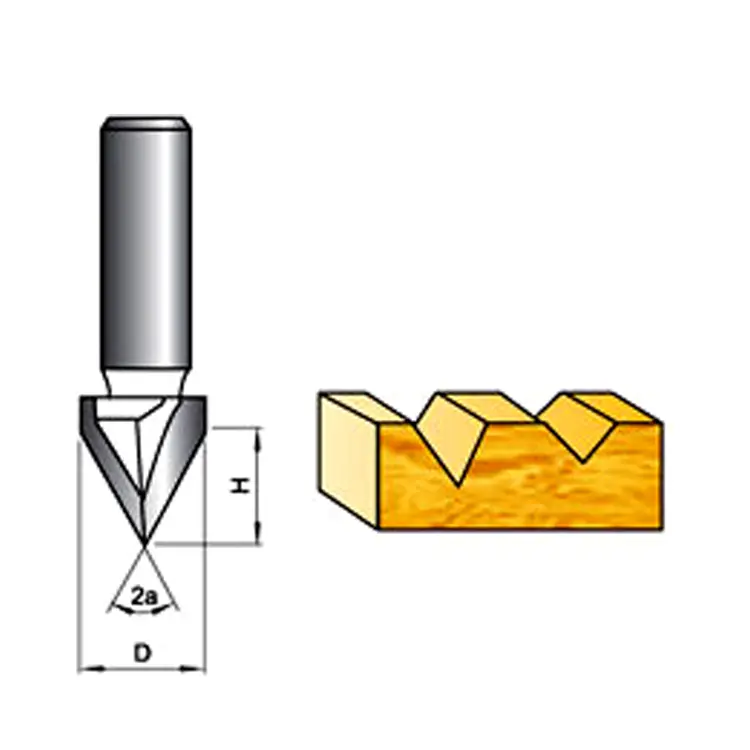

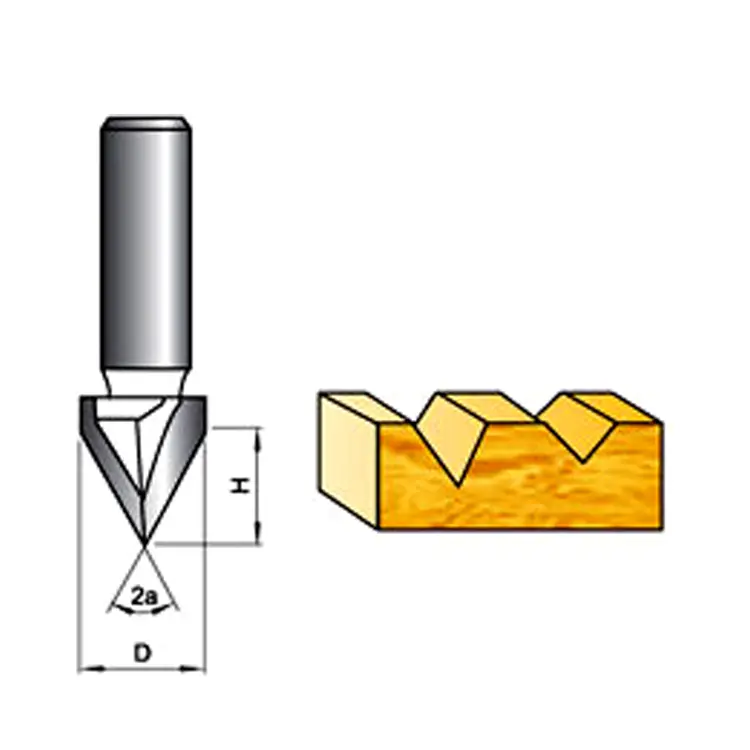

Achieve precision and expertise with JS-TOOLS carbide V-groove drill bits

Welcome to JS-TOOLS, where precision meets woodworking expertise. Our carbide V-groove drill bits are designed for CNC, handheld and benchtop milling machines. Whether you're a professional craftsman or a passionate hobbyist, our V...Read more -

Improve your woodworking skills with our high-durability drill bits

Introducing our high-durability drill bits designed to revolutionize your woodworking projects. Made from classic high-speed steel with a hardness grade of HRC 62-64, this drill bit has an extremely long service life, excellent cut...Read more -

Improve drilling efficiency with high-quality drill bits

In the world of construction and DIY projects, having the right tools is crucial to achieving the best results. When it comes to drilling, a high-quality drill bit is essential. Today, we'll explore the exceptional features of the ...Read more -

Achieving Precision and Efficiency with Tungsten Carbide Milling Cutters

When it comes to woodworking, having the right tools can make all the difference. That's why JS-TOOLS has developed a line of high quality tungsten carbide milling cutters guaranteed to enhance your woodworking projects. These cutting-edge tools combine sharp, durable ca...Read more -

Accurate and Durable with Tungsten Carbide Drills

When it comes to drilling with high precision and durability, look no further than our new solid carbide drills. These bits are engineered for long life and excellent wear resistance. With their superior performance, they surpass other hex shank bits on the market. In th...Read more -

Step Up Your Drilling Game With The Strong And Sharp Yellow Tile Drill Bit

Having the right drill bit is essential when it comes to drilling holes in a variety of materials including tile, brick, marble, glass and even plastic. That's where the strong and sharp yellow tile drill bit comes into play. Constructed of carbide, this innovativ...Read more -

Solid carbide drills for precise and durable drilling

If you are looking for drill bits with high precision, durability and long service life, then our new solid carbide drill bits are the best choice for you. These bits are extremely wear resistant and provide more accurate anchor holes than other hex shank bits on the mar...Read more -

The difference between electric hammer drill and power tool impact drill

As a DIY enthusiast or professional contractor, finding the right tool for the job can be a complex task. With the marketplace offering a plethora of options, the distinction between tools can sometimes be unclear. One such example is choosing between a hammer drill and a power tool impact drill....Read more -

What Is the Difference Between Hammer Drill and Rotary Hammer in Mechanical Principle?

Power drill is the most widely used and common electric tool in life. The principle of electric drill is well understood. A motor outputs rotating torque and drives the drill to rotate through the gearbox or other speed change mechanisms. The impact driver is generally used with a drill bit with ...Read more